During any lateral movement, lights and sirens operate to ensure safety of the crew operating adjacent to the crane. The lateral movement is controlled by a cabin along the landside wheel. They operate along two rails (waterside and landside designations) spaced based on the size of crane to be used.Ī combination of two sets of typically ten rail wheels. Ship-to-shore gantry cranes are imposing, multi-story structures prominent at most container terminals, used to load intermodal containers on and off container ships. Further confusing the issue is that gantry cranes may also incorporate a movable beam-mounted hoist in addition to the entire structure being wheeled, and some overhead cranes are suspended from a freestanding gantry. By contrast, the supporting structure of an overhead crane is fixed in location, often in the form of the walls or ceiling of a building, to which is attached a movable hoist running overhead along a rail or beam (which may itself move). The distinction most often drawn between the two is that with gantry cranes, the entire structure (including gantry) is usually wheeled (often on rails). The terms gantry crane and overhead crane (or bridge crane) are often used interchangeably, as both types of crane straddle their workload.

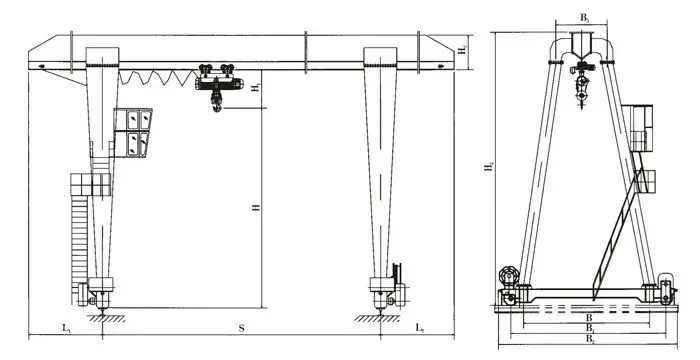

They are also called portal cranes, the "portal" being the empty space straddled by the gantry. They can range from enormous "full" gantry cranes, capable of lifting some of the heaviest loads in the world, to small shop cranes, used for tasks such as lifting automobile engines out of vehicles. Side-view of Super-PostPanamax portainer crane at the APM Terminal in the Port of RotterdamĪ gantry crane is a crane built atop a gantry, which is a structure used to straddle an object or workspace. JSTOR ( March 2011) ( Learn how and when to remove this template message).

Unsourced material may be challenged and removed. Please help improve this article by adding citations to reliable sources.

This article needs additional citations for verification.

0 kommentar(er)

0 kommentar(er)